Maker Faire Bay Area 2024

Mass Customization with 3D printed systems

Home: California, United States

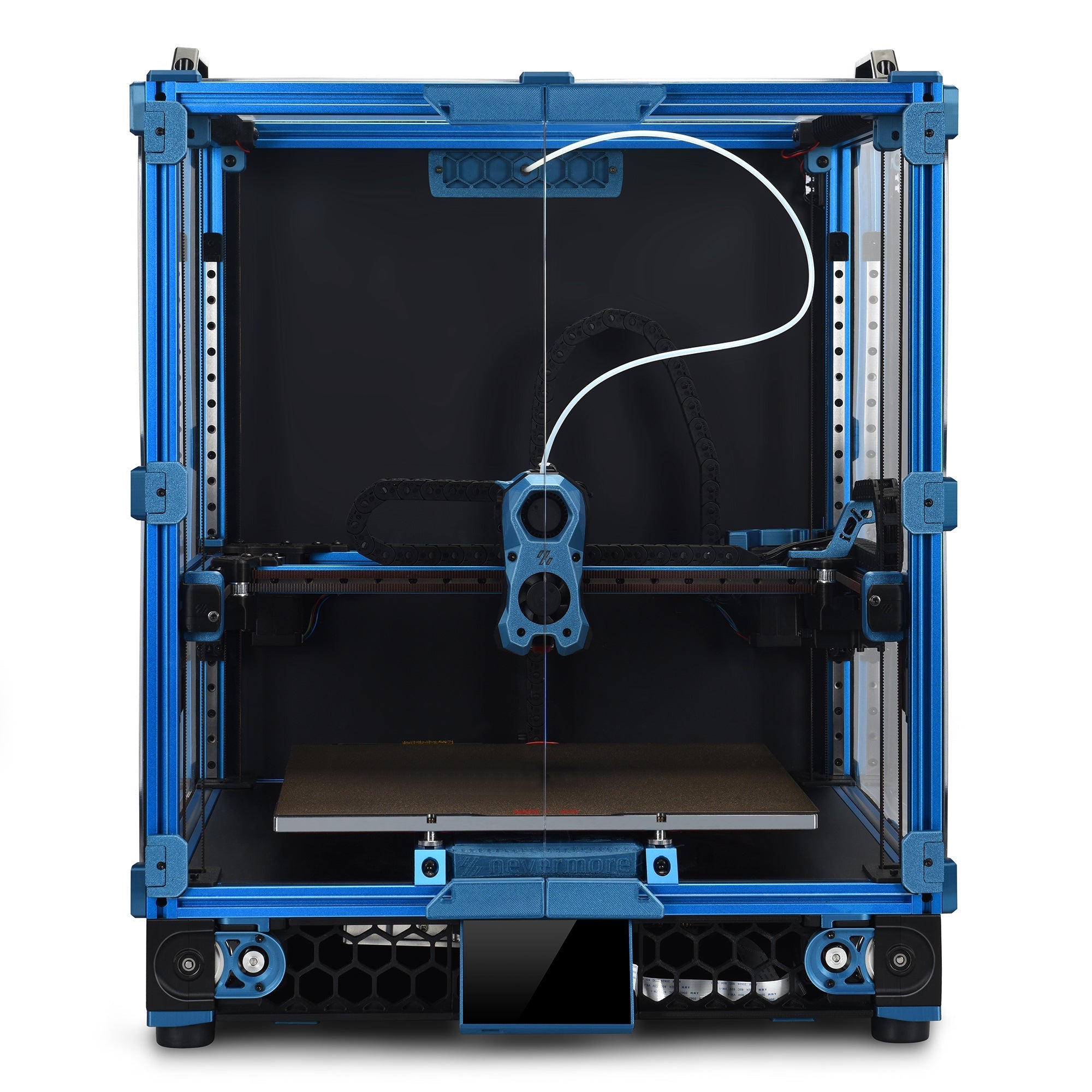

It may be tempting to 3D print the same thing again and again, but it is cheaper and faster to make the same thing using molding techniques. In order to really use the unique advantages of 3D printing, printed objects should be unique. They should be customized to an person or small group of people's needs. At the same time, getting good at CAD isn't easy. However, there are physical systems, generated by code or parametric modeling, that work with 3D printing's core advantages and are easier to use. I'd like to show off some of the community-generated systems for organization that take advantage of this mass customization such as the Honeycomb Storage Wall and the Gridfinity system, along with metal extrusions, as an example of how to take advantage of 3D printing's unique advantages

Makers

Ken Wronkiewicz

Ken is a photographer, electronics tinkerer, software engineer, and artist who has worked on Maker projects ranging from motorized circus aparatus to specialized light painting aparatus to popular models on printables.com.

What Inspired You to Make This?

I worked for a while at a 3D printed car startup where their unique value proposition was freeing car companies of the obligation to make a giant facatory that must produce a minimum number of cars a year to break even using 3D printers and unique engineering. Instead you could assemble a micro-factory to produce cars in smaller batches without the compromises that low-volume carmakers have to make right now. I had a lot of fun there, as I'd spent a lot of energy in college studying computer graphics only to end up doing software infrastructure. At around the same time, my own personal projects involving LEDs and photography started to require more and more custom fabrication so I started to design parts and send them off to get 3D printed. I'd resisted the idea of having my own 3D printer, because I only have so much space in my geekroom and something else would have to go. Eventually I realized that I did have the space, I just needed to better organize things. Thus, I got myself an Ender, primarily so that I could print organizers where helping out with my artwork was a side benefit. Which I succeeded at; over that printer's lifetime it printed exactly one Benchy. As I went through the 3D model repositories on Thingiverse and later Printables, looking for things to print, I started to spot systems. For example, the Honeycomb Storage Wall. One person won a Printables contest for the base set of pieces, but I saw all kinds of useful modules that would plug in to that system. Seeing a gap in what was available, I wrote an OpenSCAD program to generate the base plate with arbitrary sizes and uploaded it. It attracted a lot of notice, including a few 3D printing youtubers and is still getting downloaded hundreds of times a month. At the same time, a few other people commented that this kicked them into action, which meant that soon there were two really good OpenSCAD libraries to generate parametric bits. Between my Honeycomb Storage Wall and Gridfinity organization projects, furnuture made with 2020 extrusions, and electronics bits mounted on DIN rails for ease of prototyping, I thought that I should talk about this in a higher-level fashion.